Fido utilizes a damper between the rear swingarm and frame, the problem is the part does not exist. So, like most of the parts on Fido, we have to make it ourselves.

The Design

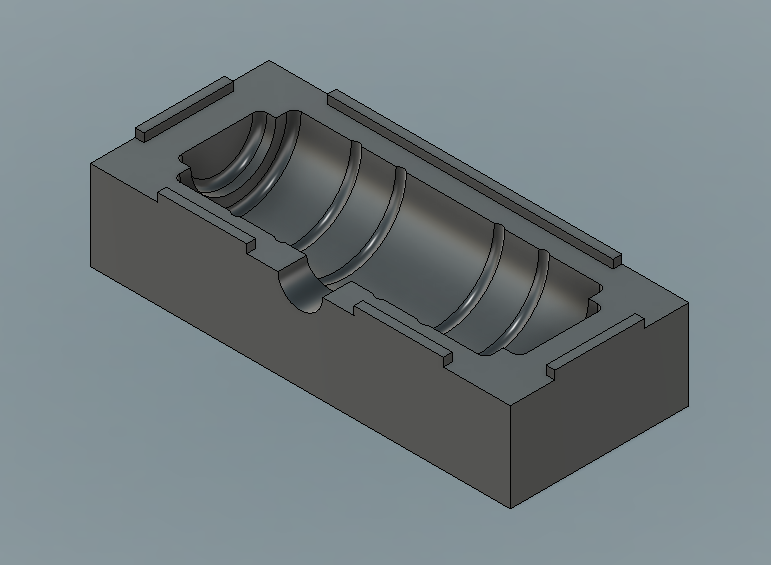

First I drew up the models for the mold in Fusion 360. The design is going to be two parts with a 10mm fill hole. Mold part A has the raised edges that lock into the cut edges on part B. The part could now be 3d printed, but in this case I decided to machine it. Back into Fusion 360 to do the tool pathing. Export to g-code and we are ready to machine.

The setup

First thing we need is a large piece of Aluminum or Plastic, good thing we have...

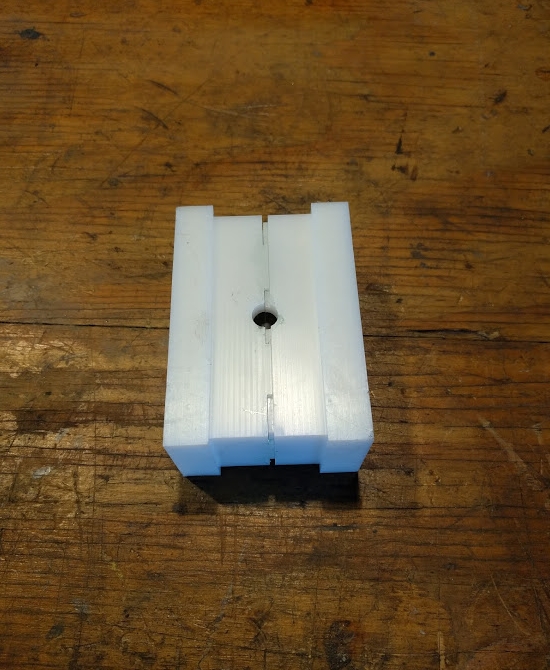

After cutting it down to something closer to the size we need. Machine machine machine.

And there it is, looks almost like the drawing. I did not machine the back side of the molds. This should help with clamp support and holding heat while the part is curing.

The Metal center

Unlike Oreos with a creamy center, this bushing has a metal center. Delicious. Looks ready to pour.

The Pour

I didn't get any pictures of the pouring. It was my first time through the process and with it being time sensitive, I did not want to jeopardize the final outcome of the part by stopping and taking pictures.

The process goes like this; preheat mold, mix up parts A and B of the polyurethane, pour into mold, post heat mold, wait about 4 hours, demold, part is ready to use about 3 days later.

The Rubber bushing

There we have it, a bushing ready to dampen.

Thanks for tuning in! I want to hear from you. What would you like to see or read about next? Post it in the comments or send me an email. Until next time, safe riding!